Ceramic Glazing Techniques & Benefits in 2026

Time of issue: 2026-01-19 15:52:00- What Are Ceramic Glazing Techniques?

- Key Differences Between Ceramic Glaze and Ceramic Body

- Why Ceramic Glazing Is Essential for Quality and Performance

- Core Materials Used in Ceramic Glazes

- Main Types of Ceramic Glazing Techniques Used Today

- Step-by-Step Ceramic Glazing Process in Manufacturing

- Ceramic Glaze Firing Methods and Temperature Ranges

- Common Ceramic Glazing Defects and How to Prevent Them

- Ceramic Glazing for Custom and OEM Production

- Quality Control Standards in Professional Ceramic Glazing

- How to Choose the Right Ceramic Glazing Technique for Your Project

- Sustainability and Safety in Ceramic Glazing

- Future Trends in Ceramic Glazing Technology

- Final Thoughts: Partnering for Manufacturing Excellence

Ceramic glazing is the process of applying a glass forming coating to fired or unfired clay, then melting it in a kiln at controlled temperatures to seal and protect the ceramic body. Ceramic glazing techniques are the key to achieving durable, food safe, and visually consistent ceramic products.

Whether you are holding a coffee mug at your desk or admiring a decorative vase in a hotel lobby, you are likely looking at the magic of ceramic glazing. With over 25 years of manufacturing experience at Dongsheng Ceramic Co. Ltd, we’ve seen how a single layer of glass-like coating can transform a simple piece of clay into a durable, food-safe, and visually stunning product.

But what exactly goes into the glazing process? If you’re wondering how professional manufacturers create smooth finishes, vibrant colors, and long lasting surfaces - you’ve come to the right place looking for answers. For wholesalers, designers, and retailers looking to source high-quality ceramics, understanding ceramic glazing techniques is the key to ensuring product longevity and brand consistency.

In this guide, we’ll break down for you the purpose of ceramic glazing, how different ceramic glazing techniques work, when to use each method, and how professionals prevent common defects in both custom and large scale production. So, without further ado, let’s begin.

What Are Ceramic Glazing Techniques?

In technical terms, a glaze is a layer of glass fused to a ceramic body through high-temperature firing. Think of it as a protective "skin." In modern manufacturing, glazing isn't just about dipping a pot in paint; it’s a sophisticated chemical process where raw minerals melt and bond with the clay surface to create a non-porous finish.

So, what exactly is the purpose of glazing in functional and decorative ceramics? Glazing serves two primary masters: function and form.

- Functional: It makes the ceramic waterproof, easy to clean, and safe for food contact.

- Decorative: It allows for an infinite palette of colors, textures (from matte to high-gloss), and artistic effects that define a brand's aesthetic.

Key Differences Between Ceramic Glaze and Ceramic Body

It is a common misconception that the color of a ceramic piece comes from the clay itself. The ceramic body (or "bisque" after the first firing) provides the structure and shape. The glaze is a separate chemical compound applied to that structure. While the body provides the strength to hold weight, the glaze provides the surface resistance to scratches, acids, and water.

| Feature | Ceramic Body (The Skeleton) | Ceramic Glaze (The Skin) |

| Primary Composition | Clay, kaolin, feldspar, and quartz. | Silica (glass), fluxes (to melt), and alumina (to stabilize). |

| Main Function | Provides the shape, structural strength, and weight of the product. | Provides waterproofing, food safety, and aesthetic finish. |

| Porosity | Can be porous (earthenware) or dense (porcelain), depending on firing. | Non-porous; it creates a sealed, glass-like barrier. |

| Texture | Usually matte, earthy, and slightly rough to the touch. | Can be high-gloss, satin, matte, or textured (like "crackle"). |

| Reaction to Heat | Hardens and "sinters" but does not melt. | Melts into a liquid state before cooling into a solid glass. |

| Color Range | Limited to the natural color of the clay (white, grey, red, or buff). | Virtually unlimited through the use of mineral oxides and stains. |

| Cleaning | Difficult to clean if unglazed (absorbs oils and stains). | Easy to wipe clean; resistant to detergents and acids. |

Why Ceramic Glazing Is Essential for Quality and Performance

When we work with global partners like Walmart and Disney, the conversation always turns to durability. Glazing is the frontline defense for any ceramic product.

How Glazing Improves Durability and Surface Strength:

Unglazed ceramic is essentially a hard sponge - it’s porous. Glazing "seals" these pores. This creates a surface that is significantly harder than the clay beneath it, making it resistant to the daily wear and tear of cutlery or industrial dishwashers.

Role of Glazing in Water Resistance and Food Safety:

Many people often ask us, “Are ceramic glazes safe for food contact?”

Well, yes, ceramic glazes are safe for food contact, provided they are formulated without lead or cadmium and fired to the correct temperature. For tableware, glazing is non-negotiable. An unglazed plate would absorb oils and bacteria, making it unsanitary. A high-quality glaze creates a vitreous (glass-like) barrier that is impermeable to liquids, ensuring the product remains hygienic and food-safe over years of use.

Aesthetic Value, Color, Texture, and Finish Control:

Glazing is where the personality of the product is born. By adjusting the glaze formula, we can achieve a "crackle" finish for a vintage look, a silky matte finish for modern decor, or a vibrant reactive glaze where no two pieces look exactly alike.

Core Materials Used in Ceramic Glazes

Understanding the chemistry of a glaze helps in predicting how it will behave in the kiln. Every glaze is a balance of three main components:

- Silica: The "glass-former." This is the primary ingredient that melts into glass.

- Fluxes: These lower the melting point of silica. Without fluxes, you’d need impossible temperatures to get the glaze to melt.

- Alumina: The "stabilizer." It keeps the molten glaze from simply running off the pot and onto the kiln shelf.

To move beyond clear glass, we add metallic oxides. Cobalt produces deep blues, copper creates greens or reds, and iron yields earthy browns. Opacifiers like Zirconium are added to make a glaze opaque rather than transparent.

How Raw Material Quality Affects Final Glaze Results

At Dongsheng, our QA/QC teams are obsessed with raw material purity. Even a tiny amount of unplanned iron in a "clear" glaze can turn a batch of white mugs a muddy yellow. Consistency in sourcing is what allows us to match a client's brand colors perfectly across 50,000 units.

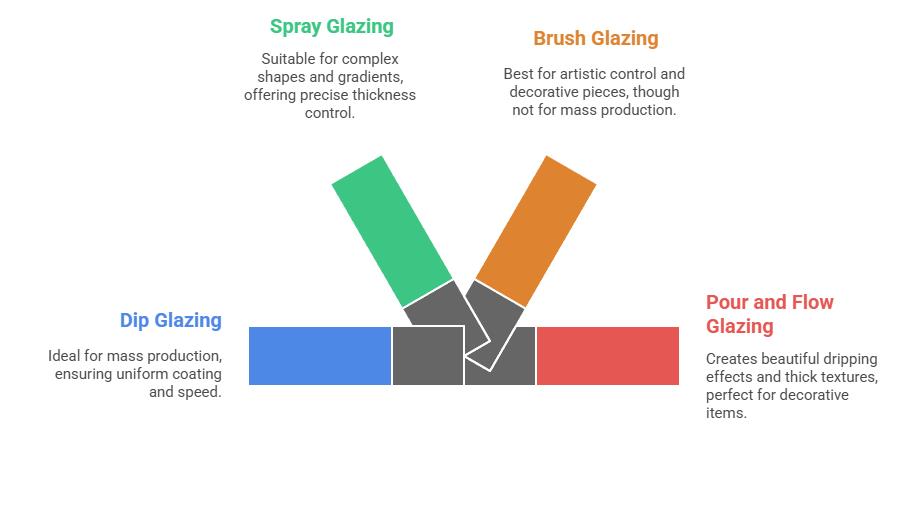

Main Types of Ceramic Glazing Techniques Used Today

Depending on the design and the production volume, we choose from four primary application methods:

1. Dip Glazing Technique

This is the "gold standard" for mass production. A bisque-fired piece is submerged into a large vat of liquid glaze.

- Pros: Extremely fast and ensures a perfectly uniform coating inside and out.

- Best for: Tableware, mugs, and high-volume orders.

2. Spray Glazing Technique

Using compressed air and specialized spray guns, the glaze is applied as a fine mist.

- Pros: Allows for gradients (ombré effects) and coating complex shapes that are hard to dip.

- Industrial Use: It’s highly efficient and allows for precise thickness control, which is vital for maintaining detail in embossed logos.

3. Brush Glazing Technique

Glaze is applied by hand using specialized brushes.

- Pros: High artistic control.

- Context: While rarely used for massive industrial runs, it is essential for hand-painted decorative pieces and "touched-up" artisanal designs.

4. Pour and Flow Glazing Technique

Glaze is poured over the piece or inside a vessel and swirled around.

- Pros: Creates beautiful "dripping" effects and thick, luscious textures.

- Best for: Decorative vases and unique accent pieces.

Step-by-Step Ceramic Glazing Process in Manufacturing

The transition from raw clay to a finished masterpiece is a disciplined journey.

- Surface Preparation: Before glazing, every piece must be cleaned. Dust or oil from a worker's hand can cause the glaze to "crawl" or peel off.

- Glaze Application: Using one of the methods above, the glaze is applied.Thickness is measured in millimeters; too thin and it looks "dry," too thick and it may bubble.

- Drying: The glazed pieces must be completely dry before entering the kiln. Any trapped moisture can turn to steam and cause the piece to explode.

- Final Glaze Firing: The pieces are loaded into kilns and heated to their maturing temperature. This is where the chemical "magic" happens and the powder turns into glass.

- Cooling: Cooling must be slow and controlled. Rapid temperature drops can cause the glaze to "craze" (develop tiny cracks).

Ceramic Glaze Firing Methods and Temperature Ranges

According to research shared by the American Ceramic Society, glaze formulation and firing accuracy directly impact strength, hygiene, and product lifespan. Temperature is the variable that changes everything.

- Low-Fire (950°C - 1100°C): Known for bright, vibrant colors. Often used for decorative earthenware.

- Mid-Fire (1180°C - 1240°C): The "sweet spot" for many modern commercial ceramics, offering a balance of durability and color variety.

- High-Fire (1250°C - 1300°C): Used for stoneware and porcelain. These are the most durable and chip-resistant products.

Oxidation vs. Reduction Firing

- Oxidation: Fired with plenty of oxygen. Colors are predictable and consistent.

- Reduction: Oxygen is starved from the kiln.This pulls oxygen out of the metal oxides in the glaze, creating unique, "toasty," and variegated colors.

Common Ceramic Glazing Defects and How to Prevent Them

Even with 25 years of experience, ceramics can be temperamental. Our job is to prevent these common issues:

- Crawling: The glaze pulls away from the surface, leaving bare spots. Usually caused by dust on the bisque.

- Pinholing/Blistering: Tiny bubbles or holes. This often happens if the kiln is heated too quickly and gases can't escape.

- Crazing: A network of fine cracks. This happens when the glaze and the clay body expand and contract at different rates. We solve this by "fitting" the glaze chemistry to the specific clay body.

Ceramic Glazing for Custom and OEM Production

As a professional manufacturer, we don’t just "make pots" - we solve problems for brands.

A glaze used for a garden pot is fundamentally different from a glaze used for a Disney-licensed coffee mug. We help clients choose the right finish based on whether the product needs to be microwave-safe, dishwasher-safe, or frost-resistant for outdoor use.

Furthermore, large retailers like Target or Michael's require strict color matching. We use laboratory-grade testing to ensure that the "brand red" on a production run of 10,000 units is identical to the approved sample.

Quality Control Standards in Professional Ceramic Glazing

Quality isn't an accident; it's a system. At Dongsheng, we maintain a strict QA/QC team that monitors:

- Raw Material Inspection: Testing every batch of minerals for purity.

- Sample Testing: A 7-12 day window where we perfect the glaze on a prototype before mass production begins.

- Third-Party Inspections: We welcome client-appointed inspectors (like SGS or Intertek) to verify that our glazing meets international safety and aesthetic standards.

How to Choose the Right Ceramic Glazing Technique for Your Project

Selecting the right ceramic glazing technique depends on how the product will be used, how it should look, and how it will be produced. There is no single best method for every project. The right choice comes from matching technical needs with practical goals.

1. Finding the Right Fit for Your Product

- For High-Volume Tableware: Dipping is your best friend. It’s the fastest way to get a perfectly smooth, food-safe finish on thousands of mugs or plates while keeping costs down.

- For Intricate Home Decor: If your design has lots of nooks, crannies, or embossed logos, Spraying is the way to go. It prevents the glaze from pooling in the details and obscuring your design.

- For High-End "Artisan" Collections: If you want that "handmade" look that customers pay a premium for, Pouring or Reactive Glazing creates those beautiful, organic drips and color variations that make every piece unique.

2. Balancing Budget and Scale

- Lead Times: Dipping and spraying are highly efficient for our 35-60 day mass production windows. More complex, multi-layered hand-painted glazes may require additional time.

- Cost Efficiency: Uniform, single-color glazes are the most cost-effective. Specialized effects - like metallic lusters or cracked "ice" glazes - require more expensive raw materials and higher precision during firing.

3. Market Standards and Compliance

- Export Requirements: If you are shipping to North America or Europe, your glaze must be lead-free and cadmium-free. We ensure all our glazes meet these rigorous safety standards before production even begins.

- Durability Needs: Will these be used in a busy restaurant (industrial dishwasher safe) or sit on a mantle (decorative)? High-fire glazes are essential for anything that needs to withstand daily scrubbing.

Sustainability and Safety in Ceramic Glazing

Sustainability and safety are now central considerations in modern ceramic glazing. Manufacturers and buyers alike are paying closer attention to how glazes impact health, the environment, and long term product use.

1. Focus on food safe and lead free formulations

- Glazes for tableware and drinkware must meet strict food contact safety standards

- Lead free and cadmium free glazes reduce health risks and improve consumer trust

- Certified testing ensures products are safe for daily use

2. Reducing environmental impact in glazing processes

- Efficient kiln firing lowers energy consumption and emissions

- Water recycling systems help reduce glaze waste during application

- Improved material sourcing supports more responsible production

3. Worker safety and quality assurance

- Controlled glaze mixing minimizes airborne particles

- Protective handling procedures reduce exposure risks

- Clear documentation and testing strengthen quality control

Future Trends in Ceramic Glazing Technology

Ceramic glazing technology is advancing rapidly as manufacturers invest in smarter, cleaner, and more precise production methods. One of the most noticeable shifts is the increased use of automation and digitally controlled glazing systems.

Automated spray lines and computer guided thickness control help reduce material waste while improving consistency across large production runs. This level of precision is especially important for custom and private label orders where color accuracy and surface uniformity must remain consistent from sample to mass production.

Another key trend is the growing demand for advanced surface effects and functional glazes. Matte finishes, reactive glazes, and layered textures are becoming more popular as brands look to differentiate their products in competitive markets.

At the same time, functional glaze developments such as improved scratch resistance, heat tolerance, and easier cleaning are adding real performance value beyond appearance. These innovations allow ceramic products to meet higher expectations for durability and everyday use.

Sustainability is also shaping the future of ceramic glazing. Energy efficient kilns, optimized firing cycles, and environmentally responsible glaze formulations are helping manufacturers reduce environmental impact while maintaining quality.

As technology continues to evolve, ceramic glazing will remain a critical area where craftsmanship, material science, and innovation come together to define the next generation of ceramic products.

Final Thoughts: Partnering for Manufacturing Excellence

Ceramic glazing is where science meets art. It is the difference between a product that sits on a shelf and one that becomes a household staple. With over 25 years of experience, Dongsheng Ceramic Co. Ltd combines the wisdom of traditional craftsmanship with the precision of modern industrial standards.

Whether you are looking for high-volume OEM production or a bespoke custom design, our commitment to quality and transparency ensures your vision is realized exactly as intended. Explore our exclusive ceramic products collection from our catalog to see how professional glazing elevates design and performance.

Are you ready to bring your ceramic designs to life with professional-grade glazing? Contact our team today to discuss your project requirements or to request a sample. Our team is always ready to support your ceramic customization needs.

RECENT POSTS

- Ceramic Cookware vs Cast Iron: What Should You Choose?

2026-01-19

- Ceramic Glazing Techniques & Benefits in 2026

2026-01-19

- The Benefits of Wholesale High-Quality Ceramic Products for Retailers

2025-12-17

- Can You Make an Ashtray with Air Dry Clay? Pros, Cons, and Safer Alternatives

2025-12-17

- The Impact of Ceramic Materials in Energy-Efficient Buildings: Benefits and Applications

2025-12-04

- Top 7 Ceramic Cookware Health Benefits: Why It’s a Safer Choice for Your Kitchen

2025-12-04

- How to Clean Ceramic Planters and Improve Their Lifespan?

2025-11-17

- 15 Best Ceramic Holiday Gift Ideas for 2025: Thoughtful, Elegant & Heartfelt

2025-11-17