How Ceramic Cone Temperatures Affect Your Kiln Firing Process

Time of issue: 2024-10-10 16:22:03- What Are Ceramic Cone Temperatures?

- The Importance of Proper Firing Temperatures

- Choosing the Right Ceramic Cone for Your Project

- How to Use Ceramic Cones in Your Kiln Firing Process

- Common Issues When Using Ceramic Cones

- Advantages of Using Ceramic Cones Over Digital Thermometers

- Tips for Achieving Optimal Firing with Ceramic Cones

- Ceramic Cone Temperatures vs. Pyrometric Cones: Key Differences

- Frequently Asked Questions About Ceramic Cone Temperatures

- Final Thought

How do ceramic cone temperatures affect your kiln firing process? The answer lies in their ability to precisely measure heat work, ensuring consistent and accurate firing results. Ceramic cones are essential tools for potters and ceramic artists, indicating when the desired temperature has been reached inside the kiln. By using ceramic cones, you can ensure your pieces are properly fired, avoiding common issues like under-firing or over-firing, which can lead to cracking or color distortion.

Each cone corresponds to a specific temperature range, making them a reliable guide for achieving the right glaze and strength in your ceramics. Whether you're firing earthenware, stoneware, or porcelain, understanding how these temperatures affect your process is key to producing high-quality work. At Global Reach Ceramic, we provide the knowledge and tools you need to master your kiln firing, ensuring that every project turns out perfectly.

Ready to take your ceramics to the next level? Keep reading to unlock the full potential of your kiln firing process!

What Are Ceramic Cone Temperatures?

The Role of Ceramic Cones in Firing

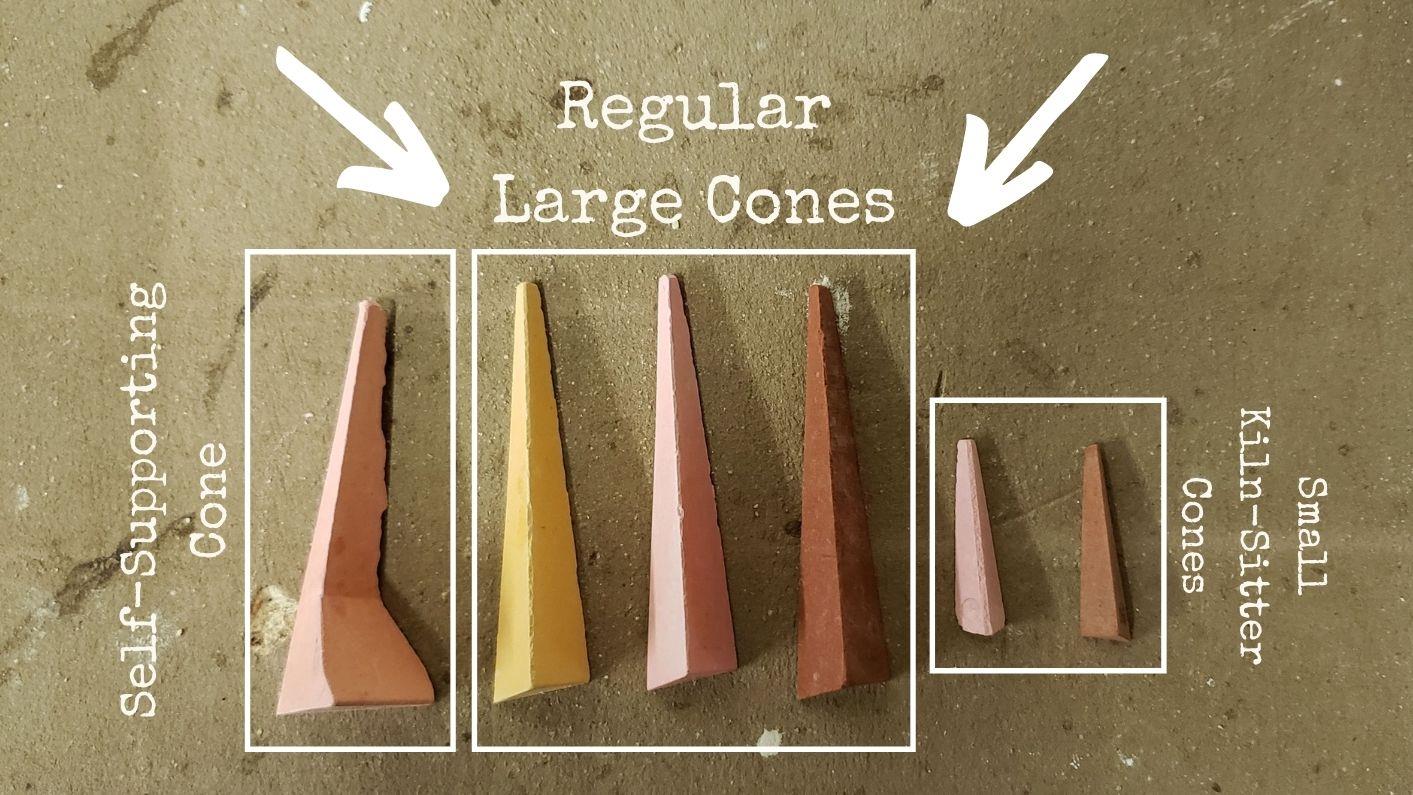

Ceramic cones are essential tools for controlling and monitoring ceramic cone temperatures during the firing process. These small, pyramid-shaped cones are made from a carefully formulated ceramic material designed to melt and bend at specific temperatures. Unlike digital thermometers, which only measure air temperature, ceramic cones gauge heat work, the combined effect of temperature and time inside the kiln. This makes cones more reliable for accurately assessing how well your ceramics are being fired.

The role of these cones is crucial in achieving optimal firing results, as they provide potters with a visual indicator of when the desired temperature has been reached. When the cone bends, it signals that the clay or glaze has reached the proper maturation point, ensuring durable and visually appealing ceramics.

Understanding Heat Work in Kilns

Heat work refers to the total effect of temperature combined with the time the ceramics are exposed to heat during the firing process. Ceramic cone temperatures represent the amount of heat work required to properly mature a ceramic piece, rather than just the air temperature inside the kiln. For example, firing at a higher temperature for a shorter time may produce the same heat work as firing at a lower temperature for a longer period.

Potters must understand heat work to produce consistent results, as firing too quickly or too slowly can impact the quality of the final product. Ceramic cones are specifically designed to melt at different heat work levels, providing a reliable measure of whether the correct amount of heat has been applied over time. This is critical in achieving proper maturation for both clays and glazes.

Common Ceramic Cone Numbers and Their Temperature Ranges

Ceramic cones are numbered based on their melting temperatures, ranging from Cone 022 (about 1112°F), used for low-temperature firing, to Cone 10 (about 2381°F), ideal for high-fire stoneware or porcelain. Each cone number corresponds to a specific temperature range, indicating when the firing process has reached the desired maturity for your pieces.

For instance, Cone 06 (1830°F) is often used for low-fire clays like earthenware, while Cone 6 (2232°F) is typically used for mid-range stoneware and glazes. Potters must choose the correct cone number based on the type of clay and glaze they are working with. Using the wrong cone can result in under-firing or over-firing, leading to defects like cracks, poor glaze quality, or weak ceramics.

The Importance of Proper Firing Temperatures

Effects of Under-Firing and Over-Firing on Ceramics

Achieving the correct ceramic cone temperatures is essential to avoid issues like under-firing and over-firing. Under-firing occurs when the ceramic piece doesn’t receive enough heat work, causing the clay to remain soft and fragile. The glaze may also appear dull or incomplete, leaving the surface unsealed and vulnerable to damage.

On the other hand, over-firing results from too much heat work, which can cause the clay to warp or even melt. The glaze may run or develop an unwanted finish, and the structure of the ceramic can weaken, leading to potential cracks. Both of these outcomes can ruin your ceramics and waste valuable time and materials, making it crucial to control firing temperatures accurately.

How Cone Temperatures Impact Glazes and Strength

Ceramic cone temperatures play a vital role in determining the final quality of your ceramics, especially regarding glaze adherence and overall strength. At the right temperature, glazes melt properly and form a smooth, glossy finish that bonds well with the clay body. If the firing temperature is too low, the glaze will not fully melt, resulting in rough, uneven surfaces and underdeveloped colors.

The strength of the ceramic piece also depends on hitting the correct cone temperature. At the optimal heat work, the clay body undergoes vitrification, where the particles fuse together, creating a dense, durable structure. Over-firing, however, can make the clay too brittle or cause the glaze to lose its integrity. This is why precision in firing is essential for both functional and decorative ceramics.

Why Accuracy in Firing Matters for Potters

For potters, accuracy in firing is the difference between a successful batch and one that fails. Consistently reaching the right ceramic cone temperatures ensures that your pieces are not only aesthetically pleasing but also structurally sound. Accurate firing impacts every stage of the process, from glaze application to final strength, meaning potters must rely on ceramic cones to monitor and control heat work effectively.

Choosing the Right Ceramic Cone for Your Project

Cone Numbers for Earthenware, Stoneware, and Porcelain

When selecting the right ceramic cone temperatures for your project, the type of clay you’re working with—earthenware, stoneware, or porcelain—is a key factor. Earthenware is typically fired at lower temperatures, with Cone 06 to Cone 04 (1828°F - 1945°F) being common ranges. This ensures the clay matures without becoming overly brittle, and it’s perfect for pieces like decorative tiles or dinnerware.

For stoneware, you’ll generally use Cone 5 to Cone 6 (2167°F - 2232°F), which allows for a durable, dense finish suitable for functional ceramics like mugs or vases. Porcelain, known for its strength and translucency, is fired at much higher temperatures, often around Cone 10 (about 2381°F), which fully vitrifies the clay and produces a very smooth, strong final product.

Selecting the Right Cone for Specific Glazes

Glazes are highly sensitive to ceramic cone temperatures, and choosing the correct cone number for your glaze type is crucial to achieving the desired finish. Low-fire glazes, typically used with earthenware, will mature around Cone 06 to Cone 04, offering a vibrant, glossy finish that works well for decorative pieces.

Mid-fire glazes, often paired with stoneware, should be fired at Cone 5 to Cone 6. These glazes are known for their durability and subtle finishes, making them popular for functional ware. For high-fire projects involving porcelain, Cone 9 to Cone 10 is necessary to mature the glaze, creating a smooth, durable surface with deep, rich colors.

Factors That Affect Cone Selection: Kiln Type, Firing Speed, and More

Several factors can affect your choice of ceramic cone temperatures, including the type of kiln, the speed of firing, and the size of your pieces. Electric kilns are known for their consistent heat, which can make cone selection more straightforward, while gas kilns may require more attention to airflow and atmosphere.

Firing speed is another critical factor; faster firings require lower cone numbers to prevent over-firing, while slower firings allow the heat to penetrate the clay more deeply, which can impact your final results. Always consider these variables when choosing your cone number to ensure your ceramics fire evenly and successfully.

How to Use Ceramic Cones in Your Kiln Firing Process

Proper Placement of Cones Inside the Kiln

Proper placement of ceramic cones in your kiln is essential for achieving accurate firing results. Cones should be placed at eye level in a location that is easily visible through the kiln’s spyhole or peep hole, allowing you to monitor their progress without opening the kiln door.

For large kilns or kilns that may have uneven heating, it’s recommended to place cones at various locations—such as the top, middle, and bottom shelves—so you can track temperature variations throughout the firing chamber. Proper placement ensures you can easily read and interpret the cones during the firing process and make adjustments as needed.

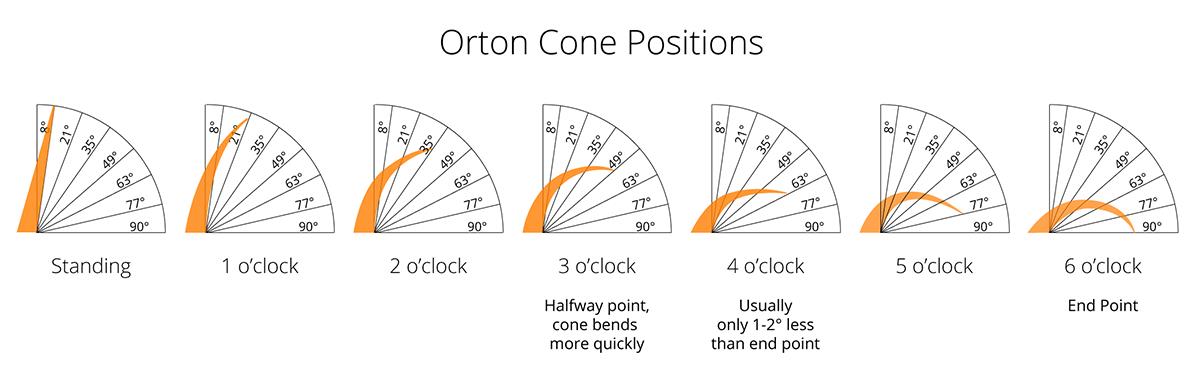

How to Read and Interpret Cone Results

Reading ceramic cone temperatures is straightforward if you know what to look for. When a cone reaches its specified temperature, it will begin to bend. A properly fired cone will bend at a precise angle—about 90 degrees. If the cone is standing upright, it means the kiln hasn’t reached the desired temperature yet. A cone that has completely melted or slumped means the kiln has over-fired, and your pieces may be at risk of damage.

By monitoring the cones during firing, you can determine whether the kiln is firing too hot or too cold, and you can make necessary adjustments for future firings to avoid under-firing or over-firing your ceramics.

Using Multiple Cones for Accurate Firing

Using multiple cones—referred to as a cone pack—is a best practice for achieving accurate results. Typically, a cone pack will include three cones: one cone that’s one number lower than the target cone (guard cone), one at the target temperature (guide cone), and one one number higher (witness cone).

As the kiln heats up, the lower cone will bend first, signaling that the kiln is approaching the desired temperature. The middle cone should bend at the target temperature, and the higher cone will remain upright, ensuring you haven’t over-fired. This method allows for precise control and ensures that your ceramics are fired to the right temperature every time.

Common Issues When Using Ceramic Cones

Troubleshooting Under-Fired and Over-Fired Pieces

When your pieces come out of the kiln under-fired or over-fired, it often means there was an issue with the ceramic cone temperatures or placement. Under-firing occurs when the kiln didn’t reach the required temperature, resulting in weak, porous ceramics and dull glazes. The solution here may involve using a lower cone number in your next firing or slowing down the firing speed to give the kiln more time to reach the desired heat work.

Over-firing, on the other hand, occurs when the kiln exceeds the target temperature, leading to warped or cracked pieces and over-matured glazes. In this case, double-check your cone placement and consider using a higher cone number if necessary. Monitoring your cones throughout the process can help prevent these issues.

Why Cone Temperature May Vary in Different Kilns

Cone temperatures may vary depending on your kiln’s size, type, and heating method. Electric kilns generally provide consistent heat, but gas kilns may experience fluctuations due to uneven heat distribution. Variations in airflow, humidity, and even the kiln’s age can also cause slight temperature differences.

Understanding these variables is crucial when using ceramic cone temperatures to fire your ceramics. For larger kilns or older models, placing multiple cones throughout the kiln is recommended to ensure even temperature distribution across all shelves and sections.

Solutions for Uneven Heating in Kilns

Uneven heating is a common problem in large or older kilns, and it can cause ceramic cones to bend at different times, leading to inconsistent results. To resolve this, consider adjusting the placement of your pieces to ensure even spacing and avoid overloading the kiln, which can block airflow.

Additionally, using multiple cones in different kiln areas can help you identify hot or cold spots, allowing you to make adjustments to your firing schedule or placement in future firings. Regular kiln maintenance, such as cleaning and inspecting the elements, also helps ensure even heat distribution.

For a deeper dive into the science behind ceramics, the American Ceramic Society provides technical information and industry standards to help you refine your firing process.

Advantages of Using Ceramic Cones Over Digital Thermometers

Real-Time Temperature Readings vs. Heat Work Measurement

While digital thermometers provide real-time temperature readings inside the kiln, they only measure the air temperature at a specific moment. However, firing ceramics is about more than just reaching a certain degree. Ceramic cones, on the other hand, measure heat work, which is the combination of time and temperature that affects the ceramic materials.

Heat work tells you how much energy the ceramic has absorbed, which is vital to achieving the right consistency, glaze maturation, and overall quality of the piece. Digital thermometers might give you immediate feedback on the current temperature, but ceramic cones provide a fuller picture of whether your ceramics have been fired properly to maturity.

Why Cones Are More Reliable for Consistent Firing Results

Ceramic cones are widely regarded as more reliable than digital thermometers because they react to the actual heat work inside the kiln. Unlike thermometers, which can be influenced by temperature fluctuations and placement, cones physically melt or bend when the correct combination of time and temperature has been achieved.

This physical transformation makes them highly accurate, ensuring that your ceramics have reached the correct maturation point. Potters using ceramic cones experience more consistent results, as cones eliminate the guesswork involved in simply monitoring air temperature. This accuracy is especially important for complex firings like glazing or working with high-fire clays.

Tips for Achieving Optimal Firing with Ceramic Cones

Prepping Your Kiln for Firing Success

Proper preparation of your kiln is key to achieving optimal firing with ceramic cone temperatures. Before firing, ensure the kiln is clean and free of debris, as dust or leftover materials can affect heat distribution. Check that the kiln elements are in good condition to provide even heating throughout the chamber.

It's also important to preheat the kiln if you're working with high-moisture pieces to avoid thermal shock. Proper ventilation and airflow are crucial during the firing process, helping the kiln maintain consistent temperatures. By taking the time to prep your kiln, you can avoid common firing issues such as under-firing or uneven results.

Best Practices for Loading the Kiln

How you load the kiln can greatly impact the accuracy of ceramic cone temperatures and the overall firing results. Avoid overcrowding the kiln, as this can block airflow and lead to uneven heating. Ensure that each piece is spaced out adequately, allowing heat to circulate freely around all sides.

Place your ceramic cones at eye level on the kiln shelf, preferably where you can view them through the spy hole. For larger kilns, consider placing cones at multiple levels to monitor temperature consistency. These best practices ensure even heating and more predictable firing results.

Monitoring the Firing Process for Perfect Results

Once your kiln is loaded and firing has begun, it’s important to monitor the progress to ensure that your ceramic cone temperatures are on track. Check the cones through the spy hole at regular intervals, especially as you approach the final stages of the firing. Look for the cones to bend gradually.

The cone corresponding to your desired temperature should bend at a 90-degree angle, signaling that the piece has been fired to the correct heat work. By keeping an eye on the cones throughout the process, you can prevent over-firing and achieve the perfect results every time.

Use a Pyrometer

A pyrometer is an essential tool for any potter looking to achieve accurate firing results. It measures the kiln’s temperature throughout the firing process, giving you additional control over how heat is applied. While ceramic cones gauge heat work, a pyrometer can help you fine-tune the process by providing exact temperature readings at every stage.

Document Your Firing

Documenting each firing is a best practice for any ceramic artist. By recording the firing schedule, cone numbers, and kiln temperatures, you can build a reference log for future projects. This log will allow you to troubleshoot issues, make improvements, and maintain consistency in your work.

Ceramic Cone Temperatures vs. Pyrometric Cones: Key Differences

When to Use Pyrometric Cones Instead of Ceramic Cones

Pyrometric cones and ceramic cones are often used interchangeably, but they serve slightly different purposes. Ceramic cones are generally used to monitor heat work during standard kiln firings, while pyrometric cones are specifically designed to measure the heat work required to melt or fuse ceramic materials.

Use pyrometric cones when you need precise control over the firing process, especially for glazes or glasswork that requires careful temperature management. For more routine firing, such as bisque firings or low-fire ceramics, ceramic cones are typically sufficient for monitoring the overall firing progress.

Comparing Their Functionality and Precision

Both ceramic cones and pyrometric cones are highly precise tools for gauging heat work in the kiln. However, pyrometric cones are engineered to measure exact temperatures for specialty materials like glass, enamel, or advanced glaze work. They are typically used in industrial settings where high precision is required for firing delicate or complex pieces.

Ceramic cones, by contrast, are more widely used by potters and ceramic artists for general firing, offering reliable accuracy in most cases. While pyrometric cones offer more precision for highly specific tasks, ceramic cones are cost-effective and dependable for a wide range of ceramics.

Frequently Asked Questions About Ceramic Cone Temperatures

Can I Reuse Ceramic Cones?

Ceramic cones are single-use items because they bend or melt when exposed to heat work. Once a cone has fired to maturity, it loses its ability to measure future firings accurately. Reusing ceramic cones would provide false readings and compromise the quality of your ceramic pieces. Always use fresh cones for each firing to ensure the best results.

How Do I Know if My Cone Fired Correctly?

You’ll know if your ceramic cone has fired correctly by its final shape. The cone should bend at a 90-degree angle, meaning it has absorbed the correct amount of heat work. If the cone is standing upright, the kiln has under-fired, and if the cone is slumped flat, the kiln has over-fired. Monitoring this helps ensure that your pieces have matured to the correct point without being damaged.

What Cone Temperature is Best for Beginners?

For beginners, starting with a mid-range firing like Cone 06 to Cone 04 (1828°F - 1945°F) is recommended for low-fire earthenware projects. This range provides enough heat for proper vitrification while being more forgiving than high-fire ranges. Once you’re comfortable with low-fire clays, you can move on to Cone 5 to Cone 6 (2167°F - 2232°F) for mid-fire stoneware and glazes. These ranges are ideal for new potters learning to control heat work in the kiln.

Final Thought

Understanding ceramic cone temperatures is crucial for achieving consistent, high-quality results in your kiln firing process. Whether you're working with earthenware, stoneware, or porcelain, using the correct cones ensures that your pieces are fired to perfection, with the right balance of strength and beauty. By incorporating ceramic cones into your process, you can easily monitor heat work, avoid common firing mistakes, and enhance the durability and finish of your ceramics.

At Global Reach Ceramic, we provide high-quality plates and ceramic supplies to help you achieve optimal results in every firing. Ready to take your pottery to the next level? How can we help you choose the right tools for your next project? Get in touch with us today, and let’s perfect your firing process together!

RECENT POSTS

- Ceramic Cookware vs Cast Iron: What Should You Choose?

2026-01-19

- Ceramic Glazing Techniques & Benefits in 2026

2026-01-19

- The Benefits of Wholesale High-Quality Ceramic Products for Retailers

2025-12-17

- Can You Make an Ashtray with Air Dry Clay? Pros, Cons, and Safer Alternatives

2025-12-17

- The Impact of Ceramic Materials in Energy-Efficient Buildings: Benefits and Applications

2025-12-04

- Top 7 Ceramic Cookware Health Benefits: Why It’s a Safer Choice for Your Kitchen

2025-12-04

- How to Clean Ceramic Planters and Improve Their Lifespan?

2025-11-17

- 15 Best Ceramic Holiday Gift Ideas for 2025: Thoughtful, Elegant & Heartfelt

2025-11-17